The automotive industry stands at a crossroads in its journey toward a sustainable future. Original Equipment Manufacturer (OEM) parts, integral to this evolution, have emerged as key players in the industry’s eco-friendly transformation. As we delve into the eco-friendly aspects of OEM parts, a panorama of innovation and environmental conscientiousness comes to light.

Innovative Materials Paving the Way

In the pursuit of sustainability, OEMs are increasingly turning towards innovative materials. The once conventional, resource-intensive components are making way for bioplastics, recycled metals, and organic textiles. This paradigm shift not only reduces the carbon footprint of these parts but also diminishes the strain on virgin resources.

The Power of Energy Efficiency

Energy efficiency takes center stage in the discussion of sustainability. Modern OEM parts are designed with a deep-seated commitment to optimizing energy consumption. From electric power steering systems that curb energy loss to advanced ignition systems that enhance fuel efficiency, every facet of OEM production now contributes to the overarching goal of reduced energy utilization.

Durability: A Cornerstone of Eco-Friendly Design

A critical facet often overshadowed is the longevity of OEM parts. In the past, a shorter lifespan necessitated frequent replacements, magnifying the environmental impact. However, the contemporary ethos champions durability. By engineering parts that endure the test of time, the industry curtails waste production and fosters a culture of sustainability.

From Factory to Road: Supply Chain Transformation

The journey towards sustainability doesn’t halt at the factory doors. Supply chains play a pivotal role. For example, OEM parts now traverse through streamlined supply chains, minimizing transportation emissions. Just-in-time manufacturing reduces excess inventory, subsequently cutting down on resource consumption and waste generation. DPF Parts Direct is a company that is committed to sustainability. They offer a wide variety of DPF parts and accessories, all of which are manufactured using environmentally friendly practices. By choosing DPF Parts Direct, you can help to support a more sustainable future.

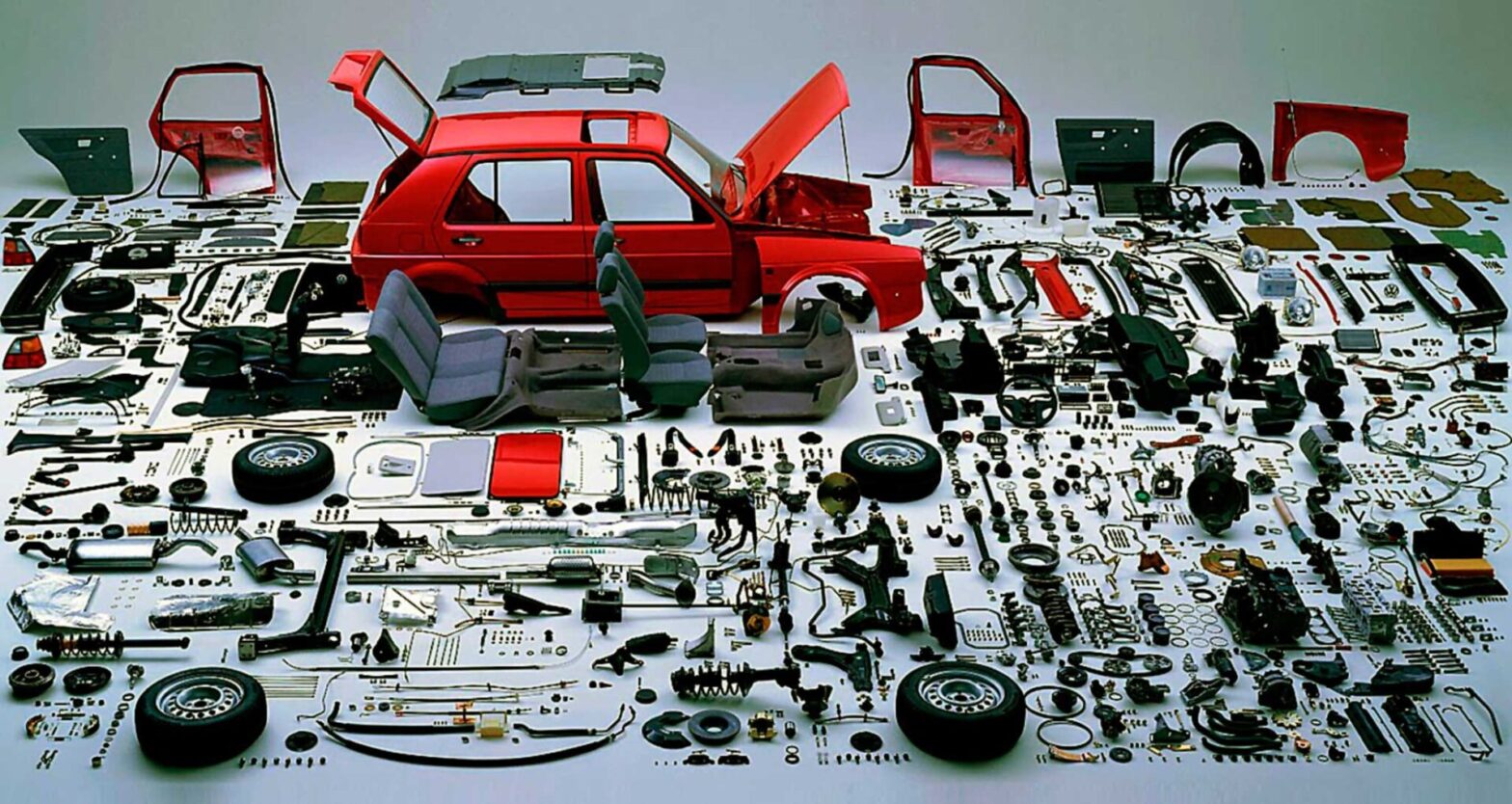

Championing Circular Economy

The circular economy model finds its manifestation in the automotive industry through OEM parts. Remanufacturing and refurbishing of components have gained momentum. This not only curbs the discard of potentially functional parts but also reduces the energy demand for crafting new replacements.

The Road Ahead: Challenges and Prospects

While the strides towards eco-friendliness are commendable, challenges persist. The integration of sustainable materials without compromising safety and performance requires meticulous engineering. Additionally, consumer awareness remains instrumental in fostering the demand for green OEM parts.

In conclusion, the automotive industry’s shift towards sustainability through OEM parts underscores a holistic transformation. The amalgamation of innovative materials, energy efficiency, durability, and a focus on circularity paints a promising picture for a greener future. The evolution, though fraught with challenges, presents a roadmap for an industry that not only moves us but also the planet forward.